The trick to extending the life and performance of your wheel end starts with something that is simple, but often overlooked: prevention. And while you’ve likely heard why it’s a good idea to keep contaminants away from wheel ends, you may not know exactly where those contaminants are coming from—or the damage they’re actually doing.

Where do contaminants come from?

Contamination can creep up in many forms depending on the geographic location of your fleet; however, the main sources are dirt, dust and water. When it comes to the former, solids like dirt and dust are abrasive. When mixed with lubricants, abrasive materials can not only damage components, they can also eventually seize the entire wheel bearing if left unchecked. When it comes to rusting and pitting, the common culprit is most often water. That’s because water dilutes the original wheel end lubricant, leading to higher operating temperatures, which can also result in seized bearings and wheel end components.

How do you completely avoid environmental contaminants?

The short answer is: you can’t, at least not fully. No matter what region your fleet is located, climate and weather will always be a factor: from rain, snow and sleet to dust storms or salty coastal conditions, not to mention the salt, chemicals and materials used to combat these conditions for highway safety.

It’s a matter of safety

When wheel-end lubricant is contaminated, problems can creep up fast. That’s because contaminated lube contains suspended particles that are hydrodynamically pushed and circulated across the seals. Eventually, the debris can tear, cut or fray the seals, resulting in catastrophic seal failure and rapid loss of lubrication. With no lubrication, bearings will run dry, potentially causing a host of safety hazards: soaked brake shoes, wheel-off conditions, even potential fires. When it comes to water—whether from driving through puddles or pulling into a loading dock with standing water—saturated lube will dramatically increase temperature in the wheel bearings from metal-to-metal contact, creating a safety issue at high speeds.

Prevention is everything

Proper wheel end maintenance and knowing what to look out for can make a big impact on roadway safety. The same goes for choosing the right wheel end components.

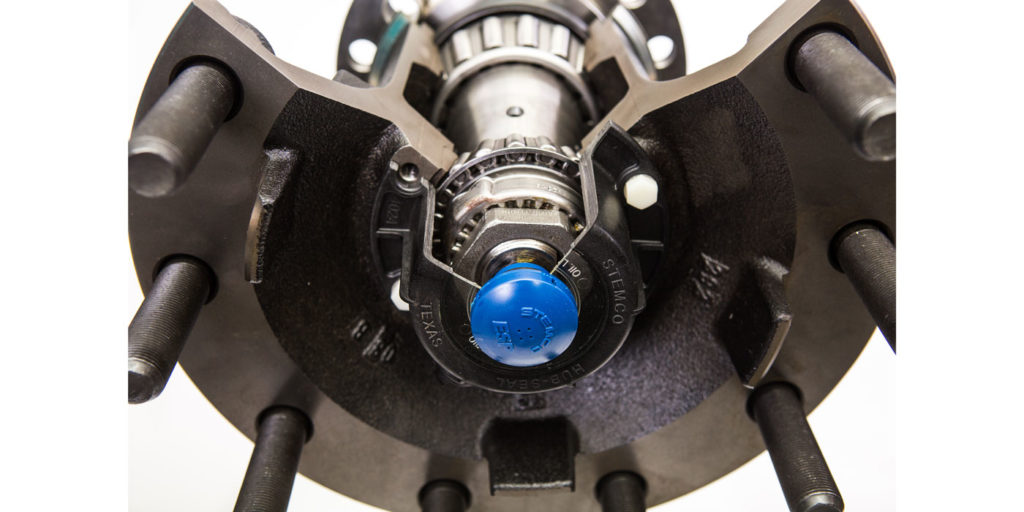

Stemco, for example, created the Sentinel Series hub caps, designed specifically for fleets that operate in high contamination environments. The Sentinel Series—available for both oil and grease applications—incorporates a venting system that releases wheel end pressure, while also using a Gore-Tex filtering system that helps eliminate both dirt and water contamination issues.

Additionally, Stemco’s ESP and ESP Plus hub cap plugs use an advanced design and innovative shielding to prevent moisture and other contaminants from entering the hub assembly.

By using the right products and keeping an eye on the performance and condition of your wheel ends, you can avoid these major setbacks, often caused by the smallest of culprits.

This article was contributed by Randy Puls, field support manager at Stemco.