With the New Year comes new engines, which meet the increasingly stringent EPA requirements and improve overall efficiency. There’s a lot to talk about, so we’re going to dispense with the editorial pleasantries and get down to brass tacks.

New engine oil category recommendations

The introduction of the new engine oil categories—API CK-4 (which replaces CJ-4) and API FA-4 (which is a brand new category)—is definitely a source of confusion when it comes to 2017 engines. Here’s what to expect when your new engine rolls off the line and into your fleet.

Cummins: For 2017, Cummins unleashed two engine offerings—the X15 Efficiency Series and X15 Performance Series. For the majority of Cummins-powered fleets, the X15 Efficiency Series will be the engine of choice between the two options. When Cummins unveiled the engines, Tim Proctor, technical leader of heavy-duty engineering for Cummins, explained that the X15 engines will come factory-filled with CK-4 oil, but was quick to point out that the engines are fully compatible with FA-4 oils as well.

Clint Garrett, the X15 product manager, echoed that. “We’re compatible with the recommend CK-4 and FA-4 oils for the X15 engine and CK-4 for the ISX12 engine in 2017,” he said. “10W-30 and 15W-40 viscosities will be offered in CK-4 oils, while FA-4 will be offered primarily in 10W-30 viscosity, as well as a 5W-30 viscosity for linehaul trucks looking to maximize fuel economy.”

An important note: 10W-30 The CK-4 oils must meet Cummins Engineering Standard (CES) 20086, and the FA-4 oils must meet CES 20087.

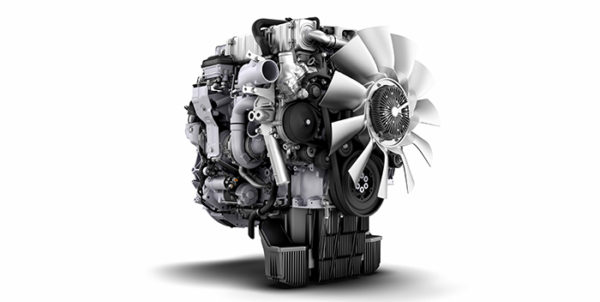

Detroit: Last year, Detroit’s medium-duty DD5 was the latest engine to join the OEM’s lineup of heavy-duty engines including the DD13, DD15 and DD16 engines. According to Greg Gusko, Detroit’s communication manager of component marketing, the recommended oil for all 2017 Detroit engines is DFS approved 93K223 FA-4 engine oil. That’s also what engines will be filled with at the factory.

International: In our January Executive Interview cover story, Steve Gilligan, vice president of product and vocational marketing for the Navistar North American Business Unit, provided details about the Navistar N13, a new 13-liter engine that will make its debut this February. In regard to the oil spec, Jim Nachtman, Navistar’s product marketing manager for on-highway trucks, explained that on the current N13 engine, “The standard factory fill oil is CJ-4 10W-30, and we offer CJ-4 5W-30 synthetic oil as a factory option. “As the industry adopts the new CK-4 classification, this will become our standard factory fill,” he continued.

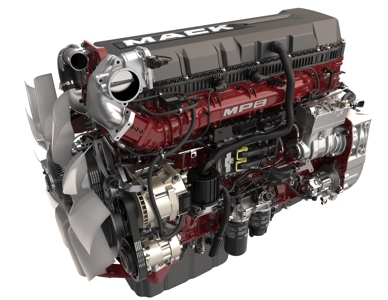

Mack Trucks: According to Scott Barraclough, Mack’s technology product manager, “Engine oils meeting the new Mack EOS-4.5 standard are recommended for our engines. These oils offer enhanced performance for oil oxidation and oil aeration control, enabling longer oil change intervals and improved efficiency.”

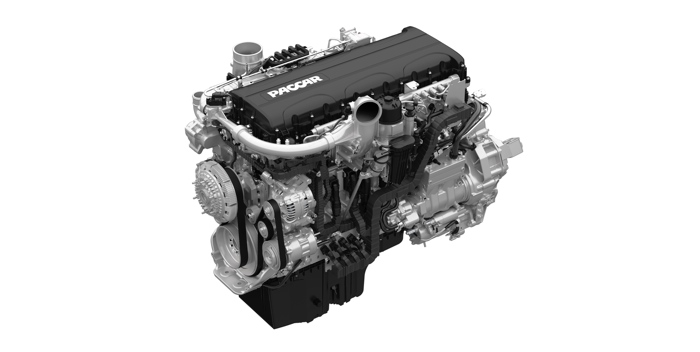

PACCAR: The PACCAR MX-11 recently joined the MX-13 in PACCAR’s engine lineup. For 2017, PACCAR is recommending CK-4 10W-30 for use in its MX series engine.

“The 10W-30 oil provides approximately 1% fuel economy benefit, as compared to 15W-40, without compromising durability in the latest generation of engines,” explained Anthony Gansle, Peterbilt Motors Co.’s market segment manager, on-highway. “The CK-4 replaces CJ-4 as a backward compatible update.”

“PACCAR recommends the use of 10W-30 CK-4 engine oil because extensive testing is done with industry oils and this combination provides the best reliability and a high level of fuel economy,” said Patrick Dean, Kenworth’s chief engineer. “PACCAR continues to evaluate usage of FA-4 oil to support enhanced fuel economy and will provide applicability guidance in 2017 after the oils are commercially available and significant durability testing ensures that our B10 engine life of 1 million miles is maintained.”

Volvo Trucks: Volvo Trucks North America brings its D11, D13 and D16 engines to the table in 2017.

“Volvo Trucks’ oil specification is called VDS4.5, SAE 10W-30, which is a version of the API CK-4 standard, but with higher performance requirements proven by more rigorous testing,” explained John Moore, product marketing manager of powertain for Volvo Trucks North America. “This oil was introduced in September 2016 as the factory fill in all of our engines and is backward compatible to legacy engines.”

Over-the-air engine updates

This year, over-the-air (OTA) engine updates via a cellular network will make their debut as an option. This means that the OEMs will be able to push engine parameter updates to your engines in much the same way that apps are updated on your smartphone.

“With over-the-air programming you get the benefit of secure, two-way engine communication, allowing you to wirelessly update your engines without a service visit,” Navistar’s Nachtman said. “That means you can remotely and effortlessly make sure that your trucks are running the most up-to-date, approved engine calibrations for optimizing fuel economy and enhancing engine reliability.”

For International’s part, the new N9, N10 and N13 engines currently offer OTA updates via Wi-Fi network through the use of the OnCommand Link device, which enables trucks to connect to a secure Wi-Fi signal. “All that’s required is that you plug in the OnCommand Link device to a nine-pin Deutsch service port, and connect to a secure Wi-Fi signal,” Nachtman explained. “While the engine is updating, make sure the truck is parked on a safe, level surface, and that the internet connection is adequate.”

Navistar has said that it will move to OTA cellular network updates in the near term.

For a look at how an OTA cellular update works, Greg Treinen, Daimler Trucks North America’s sales and marketing manager of connectivity, gave us a peek behind the curtain of what’s coming over the air for Detroit engines.

“Here is how Detroit Connect Remote Updates works: When Detroit engineers create a firmware update script for distribution, they work with the DTNA campaign manager, who determines which fleets and vehicles need to receive the update,” he explained. “The campaign manager sends notification to the identified fleets via the Detroit Connect portal.

“From there, the fleet representative can view the firmware update details and approve the update. Once the update is approved by the fleet, the encrypted, truck-specific firmware packages are then transmitted directly to the vehicles via the Detroit Connect cloud,” he continued. “At that point, the new firmware is downloaded and decrypted by the vehicle, where it is stored pending the initiation of final installation by the truck driver.

“When the truck is parked in a safe location with engine off, transmission in neutral and park brake on, the driver will receive notification in the instrument cluster display that the firmware update is ready for initiation. Once the driver initiates the installation, the process takes roughly 30 minutes to complete. The driver will receive notification about the successful completion on the instrument cluster display and then he or she can drive off with the updated truck,” he concluded.

Furthermore, fleet managers can remotely set engine parameter for maximum road and cruise speed limits, as well as idle shutdown based on time or ambient air temperature.

Cummins will offer OTA updates on its X15 Series engines as well. Additionally, using Cummins Connected Solutions, fleet managers can uprate engines’ horsepower and torque ratings to more effectively meet changing operating conditions.

“If the truck will be used in the Midwest for the first half of the year, then operating through the Rockies in the second half, the fleet manager can uprate from a 450 HP, 1,650 lb./ft. to a 500 HP, 1,850 lb./ft. rating, for instance,” Cummins’ Garrett said. “Additionally, similar to parameter settings today, a wide range of selectable options will be available to meet performance and efficiency needs over the air, like road speed governor, idle shut downs and cruise droop values.”

OTA updates will continue to roll out throughout the year and find their way into new offerings. For PACCAR’s part, Kenworth’s Dean said, “PACCAR has significant experience with over-the-air programming on non-mission critical systems and continues to evaluate the necessary hardware and software controls to make updates to mission critical systems a success. We recognize the benefit that can be achieved from parameter as well as full software updates, so this is a topic of high importance within the product development teams.”

Currently, PACCAR offers a suite of customization through its point of sale and in-field programming tools, ranging from features and settings on predictive cruise, neutral coast, vehicle speed limits, idle speeds, idle times, and vehicle acceleration rates aimed to help drivers make the most of the broad PACCAR engine power band. PTO set speeds, PTO ramp rates, hour logging, and several other features specific to stationary applications are available to tailor PACCAR engines to the job. Shift calibrations may also be tailored towards economy or performance depending on the application or specific customer preference.

Volvo Trucks’ Moore also said that OTA reprogramming is the next step in Volvo’s connected vehicle offering, but it’s not available at this time. Currently, fleet-specified engine parameters are set at the time a Volvo engine is ordered.

“Parameters are changed in most cases at point of resale, and those typically include: setting cruise speed vs. pedal speed, idle shutdown strategy, PTO set and resume speeds, coolant warmhold temperature, PTO load threshold for idle shutdown, gear down vehicle speed to encourage driving in top gear, fuel efficient eco-cruise vs. standard cruise,” Moore explained.

Streamlining service diagnostics

Today’s latest engines also integrate the latest in diagnostic technology to alert fleets to issues as they happen and provide actionable guidance—and remote diagnostics offerings keep expanding. Take Kenworth for example. New Kenworth Class 8 trucks are equipped with Kenworth TruckTech+ Remote Diagnostics, which enables fleets to view real-time vehicle health in the PACCAR Solutions portal. This year, Kenworth will expand TruckTech+ and the PACCAR Solutions portal to include a service management system powered by Decisiv, which will allow fleets to monitor the service status for their individual trucks in real-time. Kenworth TruckTech+ Service Management will also provide detailed chassis information, parts catalogs, service bulletins, parts and service promotions, as well as warranty and repair history to service technicians at Kenworth dealerships, helping them resolve issues more quickly and efficiently.

For Cummins’ part, the engine manufacturer offers Connected Diagnostics, which reads ECM data to prioritize fault codes and offer probable root cause of the fault plus clear Cummins recommendations on next steps to empower fleet managers and drivers to maximize time on the road.

“The alerts will let fleets know if the truck should schedule a check-up at the next convenience, soon, or stop now,” Cummins’ Garrett said. “Since its introduction, we have nearly 45,000 engines utilizing Connected Diagnostics with continued growth expected, spurred on by the introduction of a new Cummins customer web portal and an updated version of our mobile app.”

For Peterbilt trucks powered by either a PACCAR MX or Cummins engine, the OEM equips its SmartLinq as a standard offering. SmartLinq offers two communication paths for fleet managers—email alerts and the web-based PACCAR Solutions portal. Through these channels, the SmartLinq system provides the details of a fault code, as well as troubleshooting messages. Simultaneously, the dash display recognizes the code and informs the driver.

“A Peterbilt dealer service technician can access the same information available to a fleet for a customizable step-by-step diagnosis,” Peterbilt’s Gansle said. “The technician’s efforts are entered into the reasoning engine software, a machine-learning analog, to improve the SmartLinq diagnostic ability to pinpoint the exact cause of a fault, which improves future troubleshooting information.”

Detroit engines offer the Detroit Connect Virtual Technician remote diagnostic service. “With Virtual Technician, the notifications help fleets make the decision whether or not to take a truck to a service location right away,” DTNA’s Treinen said. “Additionally, approximately 20% of fault events transmitted by Virtual Technician have been identified as driver actionable. This means that the solution to resolving the fault can be put in the hands of the driver. In these cases, Virtual Technician sends the fleet instructions for the driver to use in resolving the issue. This can result in less time spent in the shop, and more time on the road making money.

“If the situation is critical, Virtual Technician, with the backing of the Detroit Customer Support Center (CSC), can provide additional actionable information to the fleet” Treinen continued. “Virtual

Technician transmits engine data from 60 seconds before and 15 seconds following the fault event to the Detroit CSC, where experts analyze the data and determine the problem. Detroit CSC experts will then send a follow-up notification to the fleet outlining the cause of the fault event, the recommended parts to fix the problem, and the nearest service locations with parts in stock.”

Mack trucks harness the power of its 24/7 OneCall uptime center. All Mack models come standard with Mack GuardDog Connect, a fully integrated telematics solution. GuardDog Connect proactively monitors fault codes that could potentially shut down a truck or lead to an unplanned visit to the dealer. GuardDog Connect, through Mack OneCall agents, Mack’s 24/7 service support team, enables the quick diagnosis of issues, proactive repair scheduling and parts confirmation, all while the truck remains on the job.

“Depending on the severity of the issue,” Mack Trucks’ Barraclough began, “the OneCall agents will further evaluate the issue, determine the required resolution and take the appropriate steps to remedy the problem. All of this takes place while the truck is still on the road, possibly even before a warning light comes on in the dash.”

In developing its OnCommand Connection, Navistar took an open-platform approach, partnering with 19 different telematics providers, rather than using a proprietary telematics platform. In doing so, OnCommand Connection provides diagnostic alerts on all systems on a customer’s vehicle, regardless of make, model, or engine.

“OnCommand Connection gives customers access to Fault Code Action Plans [FCAPs],” said Navistar’s Nachtman. “Navistar’s Reliability and Quality and Service Engineering teams partnered with our major supplier partners to provide customers with simple descriptions of the Diagnostic Trouble Code, a severity level, questions to ask the driver for clarification, and in many cases, route them to diagnostic and repair instructions for that fault. We’ve written approximately 18,000 FCAPs to date, and work continues as we re-rank these faults as applicable to engine and truck platform.”

Every Volvo-powered Volvo truck comes standard with telematics hardware that enables Volvo’s Remote Diagnostics, providing enhanced proactive diagnostics, detailed analysis of critical fault codes for repair planning, immediate communication if actions are required, and streamlined service procedures.

“We’ve found that the service reduces average diagnostic times by 70% and average repair times by 22%,” Moore said. “We focus on the top 50 powertrain service issues and categorize each event according to severity.

“The human factor is the biggest difference,” Moore continued. “During a diagnostic trouble code event the driver and the company’s designated decision maker are contacted by a Volvo Action Service agent at Volvo’s 24/7 Uptime Center in Greensboro, N.C. The Volvo Action Service agent explains the severity of the code and a corresponding course of action, so you know whether to seek immediate service or continue with your delivery.”